Introduction to IPS Display Technology in TFT LCDs

TFT LCD Display technology has been evolving for more than a century, continuously driving innovations in the electronic device market. In the 1990s, In-Plane Switching (IPS) technology was developed to address critical issues related to color accuracy and viewing angles in liquid crystal displays. Today, IPS display panels deliver the best colors and widest viewing angles compared to other popular display technologies, including Vertical Alignment (VA) and Twisted Nematic (TN).

This article provides a comprehensive exploration of the IPS TFT LCD display mode, offering insights into its structural design, operational mechanisms, and technological advancements. We will delve into the specifics of how IPS enhances viewing angles, the critical role of liquid crystals, and the manufacturing process behind these advanced panels. Furthermore, we will conduct a comparative analysis with the TN display mode, highlighting the unique advantages of IPS technology. This article is designed for professionals and enthusiasts alike, aiming to provide a detailed understanding of the intricacies and innovations driving the future of IPS displays in TFT LCD technology.

The Structural Design of IPS Panels in TFT LCD Displays

TFT Side (Active Matrix Side)

The TFT side of an IPS panel consists of multiple layers, each playing a crucial role in the display's operation. Typically, the TFT side includes the following six layers:

1. Gate Layer (Gate): This layer contains the gate electrodes, responsible for controlling the voltage applied to the thin film transistors (TFTs).

2. Insulating Layer (IS): This insulating layer separates the gate electrodes from the active layer, ensuring proper electrical insulation.

3. Pixel Electrode Layer (PITO): Made of transparent conductive material, usually indium tin oxide (ITO), this layer forms the pixel electrodes.

4. Source/Drain Layer (SD): This layer includes the source and drain contacts, which connect the TFTs to the pixel electrodes and driver circuits.

5. Passivation Layer (PA): The passivation layer protects the TFTs and pixel electrodes from external contaminants and damage.

6. Vertical Indium Tin Oxide Layer (VITO): This vertical ITO layer is part of the pixel electrode structure, aiding in the precise control of the liquid crystals.

CF Side (Color Filter Side)

The CF side of an IPS panel is structured differently from the TFT side and does not contain an ITO layer. Instead, it features an Overcoat (OC) layer followed by a PS (Polymer Sustainer) layer:

1. Color Filter Layer: This layer contains red, green, and blue (RGB) filters that determine the color of each pixel.

2. Black Matrix Layer: The black matrix is a grid-like structure that separates the RGB filters, improving the contrast ratio.

3. Overcoat (OC) Layer: This protective coating covers the color filters and the black matrix, providing a smooth surface for the liquid crystals and enhancing display uniformity.

4. Polymer Sustainer (PS) Layer: This polymer layer sustains the orientation of the liquid crystals, ensuring consistent and stable display performance.

This structural design enables IPS panels to achieve wider viewing angles and better color reproduction compared to TN panels. The absence of an ITO layer on the CF side, the inclusion of an overcoat layer, and the presence of a PS layer contribute to the unique properties of IPS displays, such as improved color consistency and reduced color shift at different viewing angles.

IPS.TN. and VA LCD Displays: A Comprehensive Comparison

Overview of LCD Display Technologies

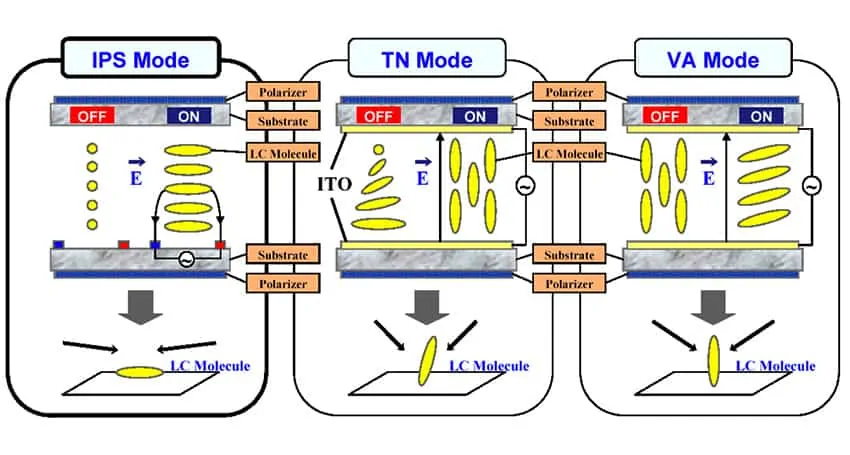

When discussing LCD display technologies, it is crucial to understand the working principles and features of different types of panels, such as TN (Twisted Nematic), IPS (In-Plane Switching), and VA (Vertical Alignment). Each technology has unique advantages that suit various application needs.

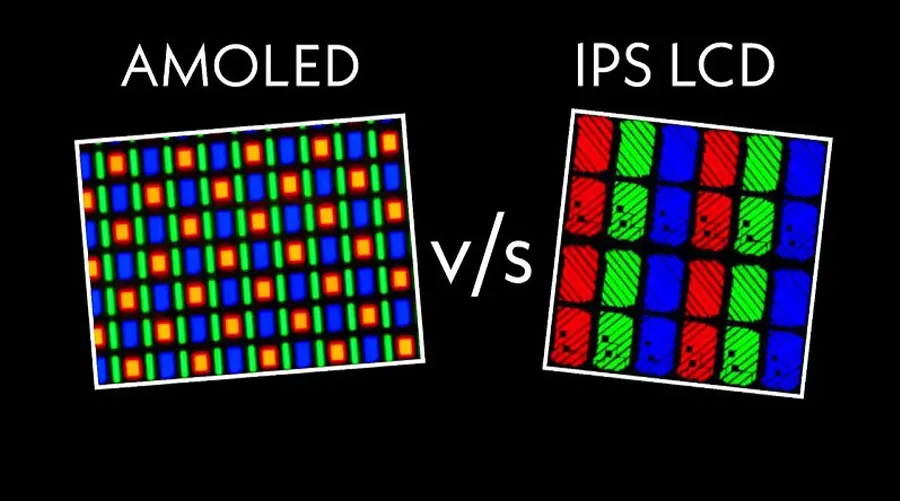

Principle of LCD Display Technology

LCD displays rely on a backlight since the liquid crystal pixels themselves do not emit light. The backlight passes through a layer of controllable liquid crystals, which can be manipulated to turn individual pixels on or off. The movement and arrangement of these liquid crystals vary depending on the type of LCD technology (such as TN, IPS, or VA).

TN (Twisted Nematic) Panels

- Liquid Crystal Alignment: In TN panels, the liquid crystals are arranged in a spiral structure. Without voltage, the crystals are twisted, allowing light to pass through; when voltage is applied, the crystals untwist, blocking or modulating the light.

- Advantages: High refresh rates, fast response times, lower cost, and energy efficiency.

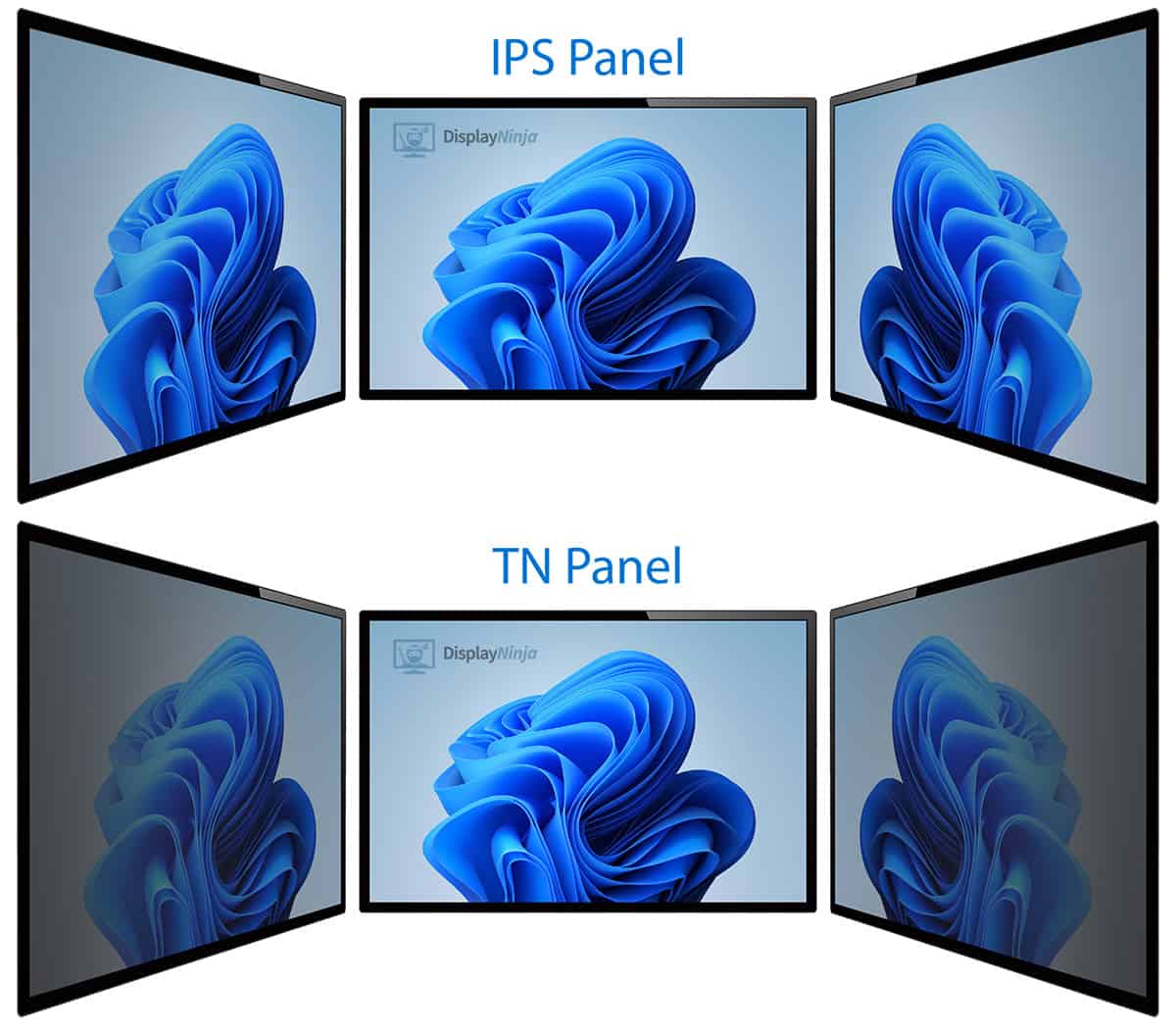

- Disadvantages: Lower color accuracy, narrower viewing angles, and lower contrast.

- Applications: Suitable for gaming displays and budget-conscious consumer electronics.

IPS (In-Plane Switching) Panels

- Liquid Crystal Alignment: In IPS panels, the liquid crystals are aligned horizontally. Without voltage, light can pass through; when voltage is applied, the crystals tilt slightly within the plane, changing the polarization of the light.

- Advantages: Excellent color accuracy, wide viewing angles, and good visibility in sunlight.

- Disadvantages: Higher cost compared to TN panels, and some models may exhibit backlight bleeding.

- Applications: High-end electronics, professional monitors, and graphic design.

VA (Vertical Alignment) Panels

- Liquid Crystal Alignment: In VA panels, the liquid crystals are vertically aligned with the panel when no voltage is applied, and they collapse when voltage is applied. This alignment provides deep blacks and high contrast ratios.

- Advantages: Deep blacks and high contrast ratios, wider viewing angles compared to TN panels, and good color reproduction.

- Disadvantages: Slower response times and limited viewing angles compared to IPS panels.

- Applications: Multimedia displays, photography and graphic design, and affordable monitors.

Summary of TN vs IPS vs VA

When choosing between TN, IPS, and VA display technologies, it is important to consider the specific requirements of the application. TN panels excel in refresh rates and response times, making them ideal for gaming and budget scenarios. IPS panels stand out with their exceptional color accuracy and wide viewing angles, making them suitable for professional work and multimedia applications. VA panels offer high contrast ratios and good color reproduction, making them ideal for multimedia viewing and budget-conscious users.

In summary, understanding the differences between TN, IPS, and VA LCD display technologies is crucial for selecting a display that meets specific needs. Each technology has its own specific advantages and limitations, suitable for different application scenarios. When making a selection, consider the importance of factors such as color accuracy, viewing angles, and response times.

The Impact of IPS Technology on Color Accuracy in TFT LCDs: A Deep Dive

In the realm of display technologies, color accuracy is a critical factor in determining the quality and usability of a screen. As a Thin Film Transistor (TFT) expert, I am excited to delve into the ways in which In-Plane Switching (IPS) technology has significantly enhanced color accuracy in TFT Liquid Crystal Displays (LCDs). This article explores how IPS technology works and why it is preferred in applications requiring high color fidelity.

Understanding IPS Technology

IPS technology was developed to address the limitations of traditional Twisted Nematic (TN) panels, particularly in terms of color accuracy and viewing angles. Unlike TN panels, where the liquid crystals are aligned in a twisted structure, IPS panels align the liquid crystals horizontally. This horizontal alignment allows for greater control over the polarization of light passing through the panel, resulting in improved color accuracy and wider viewing angles.

How IPS Enhances Color Accuracy

1. Horizontal Alignment of Liquid Crystals

In IPS panels, the liquid crystals are aligned horizontally rather than vertically. This arrangement ensures that the light passing through the panel is more evenly distributed, reducing color shifts and improving color consistency even at extreme viewing angles. From a TFT perspective, this alignment optimizes the optical properties of each pixel, ensuring higher color precision.

2. Precise Light Modulation

IPS technology enables more precise control over the modulation of light. By tilting the liquid crystals slightly within the plane, IPS panels can achieve finer adjustments in light polarization, directly impacting the transmittance of each subpixel and leading to more accurate color reproduction. This level of control is less achievable in TN panels, which results in lower color accuracy.

3. Wider Viewing Angles

IPS panels offer wider viewing angles compared to TN panels. This feature is particularly beneficial for color accuracy, as it ensures that the colors remain consistent regardless of the viewer's position relative to the screen. This is achieved by minimizing the color shift that occurs with changes in viewing angle. From a TFT structural perspective, the electrode design and liquid crystal alignment in IPS panels enable minimal changes in the optical properties of the liquid crystals, even at large viewing angles.

4. Improved Contrast Ratio

IPS panels typically provide higher contrast ratios, which contribute to more vivid and accurate colors. The deep blacks and bright whites produced by IPS technology enhance the overall color gamut, making the display appear more vibrant and lifelike. In TFT structure, the pixel design in IPS panels allows for better control of backlight transmission, contributing to higher contrast ratios.

Applications of IPS Technology

IPS technology is widely utilized in applications where color accuracy is paramount:

- Professional Graphics and Photography: IPS displays are favored by graphic designers and photographers who require accurate color representation.

- Medical Imaging: Medical professionals rely on IPS technology for precise color and contrast, essential for diagnosing and analyzing medical images.

- Broadcasting and Film Production: Filmmakers and broadcasters use IPS displays for color grading and post-production, where color fidelity is critical.

- High-End Consumer Electronics: Premium smartphones, tablets, and monitors often incorporate IPS technology to ensure a high-quality visual experience.

Conclusion

IPS technology has had a significant impact on the color accuracy of TFT LCDs. By employing horizontal alignment of liquid crystals, precise light modulation, wider viewing angles, and improved contrast ratios, IPS panels deliver superior color accuracy and consistency. As a result, IPS technology is increasingly being adopted in professional and consumer applications where color fidelity is a key requirement. Whether for professional graphics work, medical imaging, or simply enjoying a high-quality visual experience, IPS displays continue to set the standard for color accuracy in TFT LCDs.

Applications of IPS Displays

Due to their outstanding performance in color accuracy, viewing angles, and contrast ratios, IPS displays have found widespread application across various industries. As an important branch of TFT LCD technology, IPS plays a critical role in the following key areas:

1. Professional Graphics Design and Photography:

Graphic designers and photographers rely on the color consistency and accuracy provided by IPS displays. The special design of IPS panels in TFT structures ensures uniform color across the entire screen, which is crucial for creating high-quality digital content.

2. Medical Imaging:

Medical professionals depend on IPS displays for precise color and contrast. In TFT panels, the optimized electrode design and liquid crystal alignment in IPS technology enable more accurate grayscale display, which is essential for accurately interpreting medical images such as X-rays and MRIs.

3. Broadcasting and Film Production:

Filmmakers and broadcasters use IPS displays for color grading and post-production. The implementation of IPS technology in TFT structures allows for accurate reproduction of wide color gamuts (such as DCI-P3), ensuring color consistency across different scenes.

4. High-End Consumer Electronics:

High-end smartphones, tablets, and monitors often adopt IPS technology. In mobile devices, low-power variants of IPS (such as LTPS IPS) maintain color accuracy while improving energy efficiency.

5. Gaming:

Gamers favor IPS panels for their fast response times and wide viewing angles. Modern IPS technology, through optimized TFT backplane design and liquid crystal materials, significantly improves response times, reducing motion blur in dynamic images.

6. Aerospace and Military Applications:

In industries where reliability and durability are paramount, IPS displays are selected for their stability and environmental adaptability. The design of IPS in TFT structures ensures performance even under extreme temperatures and pressures.

7. Education and Research:

Educational institutions and research facilities use IPS displays for scientific visualization and data analysis. The implementation of IPS technology in TFT structures ensures high color accuracy, which is crucial for the accurate representation of complex data.

8. Retail and Advertising:

Retail businesses and advertisers benefit from the wide viewing angles of IPS displays. In TFT panels, the liquid crystal alignment in IPS ensures that product information and advertisements remain clear even at large viewing angles.

9. Smart Home Devices:

Smart TVs and home automation systems employ IPS technology to provide immersive experiences. The application of IPS in TFT structures ensures excellent display performance under various lighting conditions.

10. Transportation Systems:

Public transportation systems and private vehicles integrate IPS displays for navigation, entertainment, and safety systems. The implementation of IPS technology in TFT structures ensures performance even under vibrations and temperature fluctuations.

Latest articles

-

Why 1–2" AMOLEDs Are Key to AR/XR in 2025

Why 1–2 Inch AMOLED Displays Are Becoming Essential in the AR/XR Boom (2025 Industry Insight)body {f

-

Understanding OLED Display Technology: Principles, Performance & Applications

OLED (Organic Light Emitting Diode) displays are a class of self-emissive display technology in whic

-

From Wearables to AR Glasses – How OLED Displays Are Redefining Visual Experiences in 2025

By 2025, OLED (Organic Light-Emitting Diode) technology has transitioned from luxury smartphone disp

-

Stretched Bar LCD Displays for Retail: Boost Sales & Engagement in Supermarkets

Discover how stretched bar LCD displays enhance supermarket shelf-edge marketing, drive sales, reduc

-

Stretched LCD Solutions for Restaurants and Hospitality Venues

Stretched LCDs offer sleek, high-brightness displays perfect for restaurant menus and hospitality si